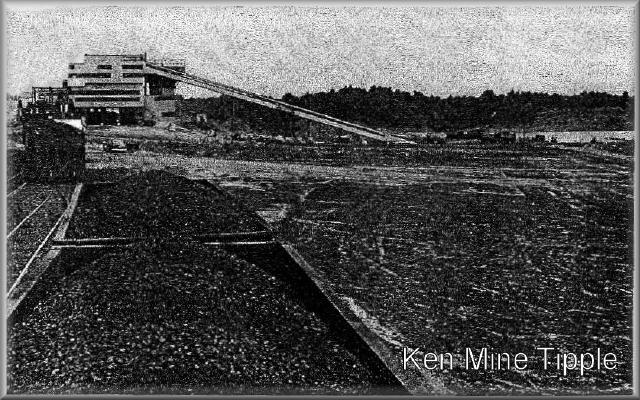

Ken Mine Tipple

Ken Mine Tipple

In 1946 and at the onset of Ken Coal Company, one of the first projects to be

started was the Ken Mine Tipple. On a smaller scale, at first, but with room to

expand and expand it did. The small tipple, at first, was continually being made

larger and after just a few years, the tipple became a modern coal prep plant.

In 1947, the first produced coal left the tipple on the way to market. Several

hoppers for train car loading were built and a separate hopper for trucks supplied

the needs for shipment of coal by trucks, as well as for the miners and local

residents. Until the early sixties, most of the homes in the Rockport and Echols

area were heated with coal. The miners were able to use their pickup trucks to

provide coal for themselves and some of their kin and neighbors. Larger trucks

were also used for local coal delivery.

In 1950, Ken Mine had ten Dart trucks that hauled the coal from the two pit areas

and dumped it into a large hopper. The first haul trucks were in the 30 to 40

ton range. The coal them moved by conveyor up to the top of the McNally-Pittsburg

tipple where it was processed and loaded on rail cars. The tipple had the capability

of producing coal from 7" to 0 size. After the railroad cars were loaded, they

were manually given a push and rolled down to a Streeter Amet Scale system that

automatically weighted a half railroad car at a time. The railroad cars continued

rolling down to a staging area where they would eventually be picked up by the

I. C. Railroad.

In this time frame, Ken Mine president, Ken R. Bixby, had a total of 110 employees.

Mr. Bixby had been in the coal business all of his life. His coal "know-how" was

gained in the Pennsylvania, Ohio, Indiana, Illinois and Kentucky coal fields. Coal

men acquainted with Bixby knew him to be an ardent baseball fan and fisherman-

"whenever he could find time."

Other key personnel included: Jim McDowell, superintendent; Howard Nunn, chief

engineer; Floyd Spriggs, master mechanic; Howard Lampson, 5561 pit foreman; and

Max Wasson, 350 pit foreman. McDowell had been in the coal business for 18 years.

The other company supervisors and foremen were also well qualified and experienced.

In 1950, a new 26'x 66'office building was completed. It was equipped with a modern

vault, finished in gravel redwood, had tile blocks on the ceilings, inlaid linoleum,

and the latest in furnishings and office equipment, with a Chrysler Air Temp Air

Conditioner. At the time, the home office of Ken Coal Company was 517 Bondi Building,

P. O. Box 70, Galesburg, Illinois.

:)

See you..........

jrd

| |