|

~~ Ken Mine! ~~

Ken Mine Machines

The BE 1450 Stripper.

In 1985, the BE 1450 Dragline, pictured above, was loaded onto three barges, that

had previously been tied together, and readied for transit down the Green River

to the Gibraltar Coal Mine, another Peabody Mine. After 20 plus years of operation

at Ken Mine, the old dragline was "Walked" to the Ken Mine River Loading Dock area,

on the Green River, where a small inlet had been cut into the bank of the river.

The three barges were "sunk" so they would rest on the bottom of the inlet. The

1450 was then "Walked" onto the barges and secured. The barge combo was then

re-floated and the loaded barges were pushed and pulled back into the Green River.

With "Tugs" attached to the front and rear of the barges, the 1450 was to make its'

first river voyage.

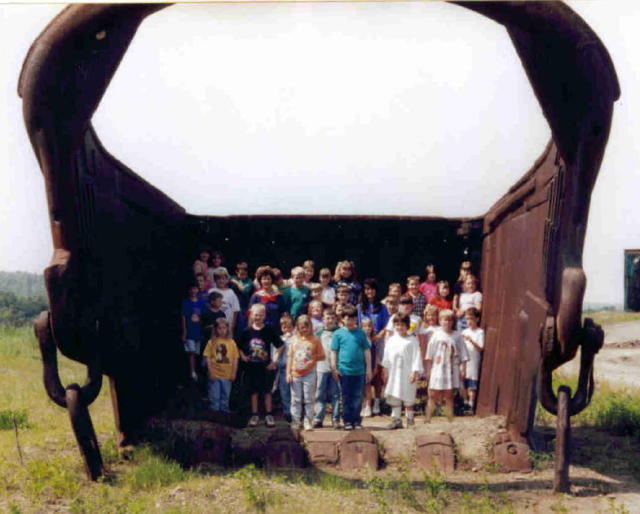

BE 1450 Bucket.

Photo from Danny Southard.

This picture is of the BE 1450 bucket after it was moved to Gibraltar Mine.

Danny Southard was taking kids from Muhlenberg County School system on a tour.

Remember, this is the BE 1450 Dragline that was built at Ken Mine in 1964.

It was a huge machine in that time frame. This dragline was operated at the mine

for over twenty years. In 1985 this enormous Dragline was shut down at Ken Mine,

loaded on a barge and shipped down river to Peabody Coal Company's, Gibraltar Mine.

It was placed in operation at Gibraltar Mine and after several years of service

and when the Gibraltar Mine closed, this machine was parked on a hillside just

off Western Kentucky Parkway. It was located just west of the Green River and

available for anyone driving the parkway to view. Rust and corrosion were

beginning to have a negative effect on the shovel when it was purchased by Martin

Marietta Minerals. The grand old machine was refurbished, on site, and painted a

bright white color. It was looking good when it was "Walked" to the Green River.

Just past where Earl Curtis had a farm, on the Rockport-Paradise Road, the BE 1450

walked the bottom land to a barge that had been partly submerged. The bottom land

had previously been frozen to prevent the big machine from sinking in the crop land.

The newly painted and refurbished BE 1450 was loaded on a barge and once again

made a river trip to the new owner's property. This time, the river trip became

a long trip and eventually became an ocean trip and the BE 1450 ended up in the

Grand Bahamas. Work well old machine. A picture follows of the white, BE 1450

being floated past Rockport on its' way to the Bahamas. How would you have liked

that trip with the shovel and then spend a few months teaching a new operator how

to operate the machine?

BE 1450.

The refurbished BE 1450 is loaded on a barge and is heading downriver. It has

just passed under the railroad bridge at Rockport and is about to go under the

highway bridge. The photographer is on the highway bridge. Gary Durham sent

me this picture and I would not doubt that he was the photographer. Thanks Gary.

The 1260 Dragline being built

at Ken.

Photo by Ray McClain.

The BE 1260 Dragline was built at Ken Mine, but it was never placed in

operation at Ken Mine. Soon after it was completed, it was loaded on two barges

and sent downriver to River Queen Mine. I don't know if the original intent was

to use the dragline at Ken or it was just easier to build it at Ken Mine and ship

it downriver. The BE 1260, with a 36 yd. bucket worked the River Queen Mine for

several years and then was moved to Vogue Mine. After Vogue was finished,the BE

1260 was moved back to River Queen. It was never dismantled during any of the

moves, but floated on river and walked from mine to mine. It still sits idle today,

and should be scrapped sometime soon.

Peabody's 1260 Dragline being

shipped downriver.

Photo by Ray McClain.

This view of the 1260 Dragline shows the relationship in the size of the dragline

as compared to the size of Green River. Note the larger tug is doing most of

the job of moving the two barges while the smaller tug at the front end helps

make some of the short turns on the river.

The 1260 Dragline passing under the Rockport Bridge.

Photo furnished by Ray McClain.

A Bucyrus-Monagham 5W Walking Dragline.

It appears that the "Stripper", whether a Dragline or a Shovel, is the only piece

of equipment at a Strip Mine. Guess it may be like the "Star Basketball" player.

The "Star" gets all of the attention and the publicity, but without the other

players, including those on the bench, the "Star" would be useless. A large

dragline or shovel is essential in any strip mine operation, but without the

"Dozers", smaller draglines, loaders, drills, and other mechanical equipment, the

stripper would be useless in a short period of time. One such piece of auxiliary

equipment is pictured above. The small dragline is a Bucyrus-Monagham 5W dragline.

To my knowledge, the 5W Dragline never operated at Ken, but an older and smaller

version did and Jimmy Blair spent a lot of his mining career operating a BM 3W

Dragline.

Somewhere in the 1948 time frame, Jimmy Blair moved to Rockport with his family

and soon fit in with the Rockport citizens. His wife and daughter were welcomed

to the community. Shirley Blair started to school at Rockport in the seventh

grade and graduated in 1953.

Jimmy Blair was the primary operator of the BM 3W dragline. He would walk that

old dragline all over Ken Mine property. His jobs including building roads, dikes,

drainage ditches, dams and anything else that he could place that dragline bucket

into. One major job was to build the "Slurry Pit". When Ken Mine Rail Tipple

started washing the coal, there was a need for a place for the gob and other

debris. This place was a large slurry pit that was located in back of the tipple.

Jimmy spent a lot of time building a dam and dredging out a place for the waste

that was left from the coal processing. The design people, if such were used,

and Jimmy, did a fine job, as this pit became a good fishing spot. It was large

enough that it took years to fill and in the meantime the good water on the back

end was clean enough to support life and especially fish. I have caught five

pound bass out of this slurry pit. On the other side of the dam, was a ditch that

drained a large area which started on one side of Happy Hollow and passed the

old garbage dump in the area from the bottom of Chinn Hill to Harvey Robinson

Grocery. Jimmy dredged this ditch and made a decent pit to fish. We always

called it the "3W" pit from the name of the machine that dug it. It could just

as easily been called the "Blair" pit.

Marion 8800 Dragline.

Photo taken by David Hope's father. Thanks Mr. Hope.

The Marion 8800 Dragline was constructed at Peabody's Homestead Mine in 1963 and

operated there until Homestead Mine was closed. It originally had a 85-yd. bucket

when built. Several years after it began stripping, there was a boom failure,

and decision time was at hand. Did the mine want to repair the machine, as such,

or did they want to make modifications? The decision was to strengthened the boom

and to re-fit it with a larger bucket. The boom was shortened and a 100 yard

bucket was installed. The M 8800 was placed back in service.

After a service period of about twenty-five years at Homestead Mines, the M 8800

was running out of places to strip. There always seem to be some confusion as

to where Ken Mine ended and where Homestead Mine started or vice-versa. The decision

was made to close Homestead and to keep Ken open for a few more years. The M 8800

was walked to Ken Mine and was able to strip for a few more years. When Ken Mine

closed, this beautiful old machine was scrapped. Such is the eventual life of

any big stripper. Most are just too large for a museum, thus they are either

buried or cut up for scrap metal.

Since Ken Mine started in the mid-forties, machines and people have worked,

around the clock, at the mine. For over a fifty year period, miners have removed

the coal from the Ken Mine area. That is some time frame. In Ken Mine Page 1,

I mentioned a few people that worked for Ken and in Ken Mine Page 2, I have

mentioned a few more people and some of the machines that were used in that fifty

plus years time frame. These two pages are in no way meant to be a summary of

Ken Mine history. I will leave that to the person that wants to work at the

project. Researching, interviewing, and other facts and information gathering

procedures are just not my cup of tea. A large book could be written, just on

the "Strippers" that have been used at Ken Mine. I have mentioned a few. I have

left a few out. When I was at Ken, in 1962, the BE 1050 was operational and

there was another stripping dragline in another pit and I can not recall the name

of that machine. I worked on it and can remember it, but can not put a name to it.

I would think that there were other strippers. There were two pits operational

at this time and to cover these two pits, there were loaders, drills, other earth

movers like dozers, trucks of all types, and various other pieces of equipment.

The working crew needed water to drink and in that time frame, Cecil Curtis had

the responsibility of supplying the entire mine with ice and water and he had a

special water truck. Another special water truck had a large water reservoir with

a pipe on the rear that contained many nozzles. It was used to "Wet Down" the

haul roads when the dust became thick enough to limit visibility. Anyone that

ever visited the mining area, on a regular basis, whether to fish, hunt or just

look made contact with this water truck. After it made a pass, the haul road

would be muddy, but the dust would be settled. If your vehicle was relatively

clean to start with, it was not after traveling over a muddy haul road. Other

special trucks like a "Cable Reel" truck were used. If there was a need for a

special rig, the miners would make the device if it could not be purchased.

There is also a long list of miners that worked at the mine. Just about every

craft of workers were represented at the mine. There was even a blacksmith. Some

of the miners worked only a year or so and left for other endeavors. A few like

Billy Welborn spent their entire working career at Ken Mine and retired. I wish

I had the time and space to mention all of the miners that worked the mine,

including the non-union or the "Company Employees", but I don't. What estimate

would a person make, as to the total number of people that worked, at one time

or another, at Ken Mine? Would that range be in the area of a thousand. Counting

Ken Underground, there may have been 500 miners working at the peak of employment.

Heck, I would raise that guess of a thousand to a few hundred more. Nothing

official here. It has been said that Ken Mine should have been called Kin Mine

due to the number of miners that were kin to each other, but with a thousand or

more miners in a small county, there had to be a lot of relatives working together.

Gary Durham has made up list of just a "Father-Son, Daughter" list and there are

52 fathers and one or more of their children on that list and guess, still counting.

All miners were special and I wish that I could have mentioned each Ken Miner, but

this web page is just not set up to do such. Hope you can enjoy what you have

seen and not be disappointed in what was not mentioned. As always, if you find

errors or information that is just not correct, please feel free to let me know.

Thanks for looking.

See you......

jrd

|